Nano-enabled product release rates and routes: Household or industrial washing

During washing, fabrics are exposed to water, detergent and mechanical friction. Washing may typically be followed by sunlight exposure during outdoor drying. In the case of nano-enabled textiles, the combination of these processes can promote ENM release as well as ENM transformations in the wash water. This page explores how potential ENM release rates, amounts and forms are measured. Many more details can be obtained from NanoFASE Report D4.2 (Release estimates inventory).

|

|

Released to |

|

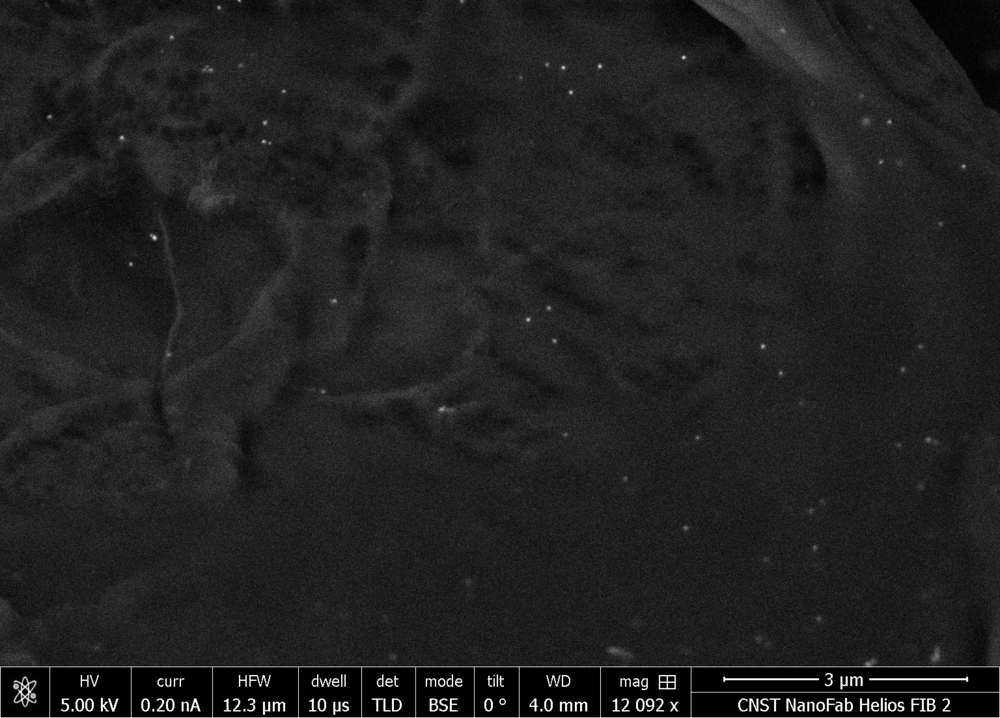

A. Scanning Electron Microscopy (SEM) image of Ag nanoparticles on textile.

|

Release rates and amounts |

|

|

Comparison between nano-enabled textiles in terms of ENM release rates and quantities is rather difficult due to the number of factors affecting release during washing. These include:

As for the relationship between textile composition and ENM release, the literature does not provide a clear conclusion [1,2]. |

ENMs most commonly added to textiles Most commonly treated textiles: Release rates (during first wash): Total release amounts: (during use phase): ENM forms observed at release: |

Release forms

Wash cycles promote ENM release either through dissociation or through mechanical abrasion forces.

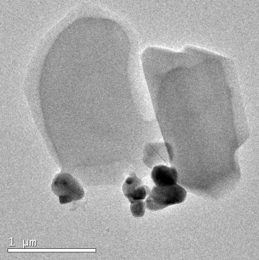

Dissociation affects soluble ENMs like silver (Ag). When exposed to washing solutions, Ag NMs may keep their properties or show dramatic changes, depending on solution chemistry (e.g. oxidant-containing powder detergents) [3]. A small fraction of dissolved silver is typically detected in all samples, in many cases having undergone transformation reactions, leading to the formation of silver-containing nanoparticles such as metallic Ag, AgCl, and Ag2S [4].

Adsorbed particles and aggregates can also be washed off due e.g. to mechanical forces or to their affinity for the washing water. It is expected that TiO2 (and SiO2) ENMs are released during washing only due to mechanical abrasion forces.

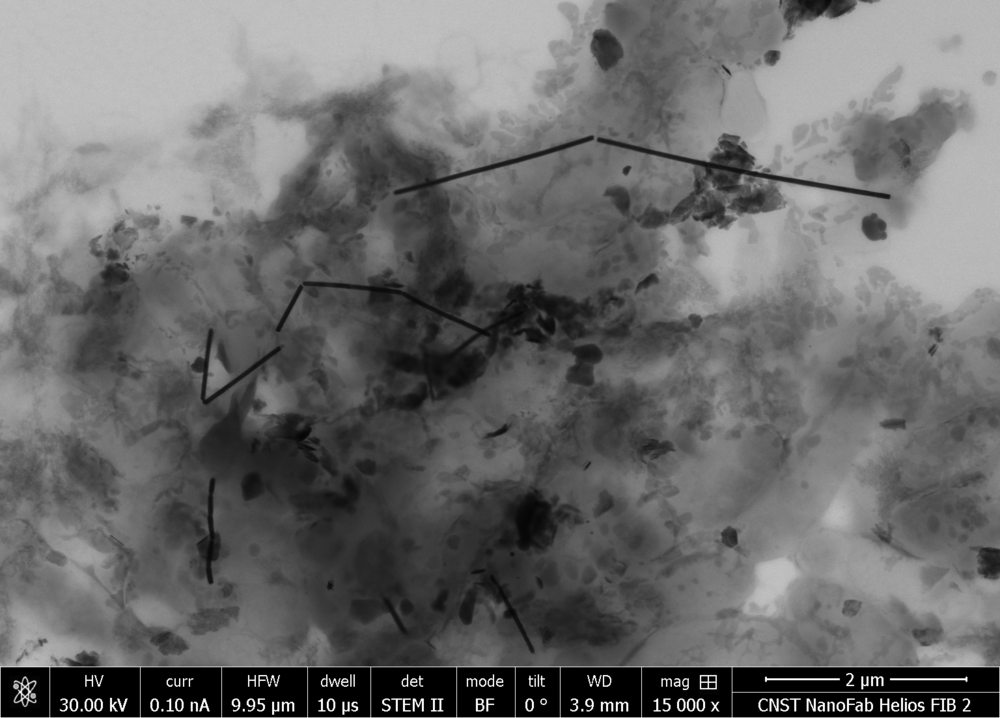

TiO2 nanoparticles collected in washing waters.

Bigger detergent particles can also be distinguished in the picture.

Image provided by LEITAT

Measurement procedure |

Case studies |

|

Typically, the washing procedure employed is an adaptation of ISO 105-C06:1994 for determining colour fastness in commercial and industrial laundering, which mimics real washing scenarios (detergent, mild wash temperature, addition of balls to provide friction during the washing). Collected waters are typically analyzed by (single particle) - ICP-MS and electron microscopy coupled with X-ray analysis. A pull-off test (ASTM D4541) has also been suggested to evaluate the adhesive strength (and indirectly, durability) of NMs binding to the fibre surfaces by applying a direct load perpendicular to the textile surface [5].

|

Antibacterial textiles |

2 Wigger H, Hackmann S, Zimmermann T, et al (2015). Sci Total Environ 535:160–171. doi: 10.1016/j.scitotenv.2015.02.042

3 Mitrano DM, Arroyo Rojas Dasilva Y, Nowack B (2015). Environ Sci Technol 49:9665–9673. doi: 10.1021/acs.est.5b02262

4 Mitrano DM, Rimmele E, Wichser A, et al (2014). ACS Nano 8:7208–19. doi: 10.1021/nn502228w

5 Kowal K, Cronin P, Dworniczek E, et al (2014). RSC Adv 4:19945. doi: 10.1039/c4ra02759k

Read more |

Read also |

|

Visit the NanoFASE Library to read summaries of these reports: NanoFASE Report D4.2 Release estimations during ENMs and nano-enabled products value chain |

Sun TY, Bornhöft NA, Hungerbühler K, Nowack B (2016). Dynamic Probabilistic Modeling of Environmental Emissions of Engineered Nanomaterials. Environ Sci Technol 50:4701–4711. doi: 10.1021/acs.est.5b05828 De Falco F, Gullo MP, Gentile G, et al (2017) Evaluation of microplastic release caused by textile washing processes of synthetic fabrics. Environ Pollut 236:916–925. doi: 10.1016/j.envpol.2017.10.057 |

Contact

Socorro Vázquez-Campos

Socorro Vázquez-Campos

Email: svazquez@leitat.org

Alejandro Vilchez

LEITAT Technological Center

Barcelona, Spain