NanoFASE Case study: INOTEX Antibacterial Textiles

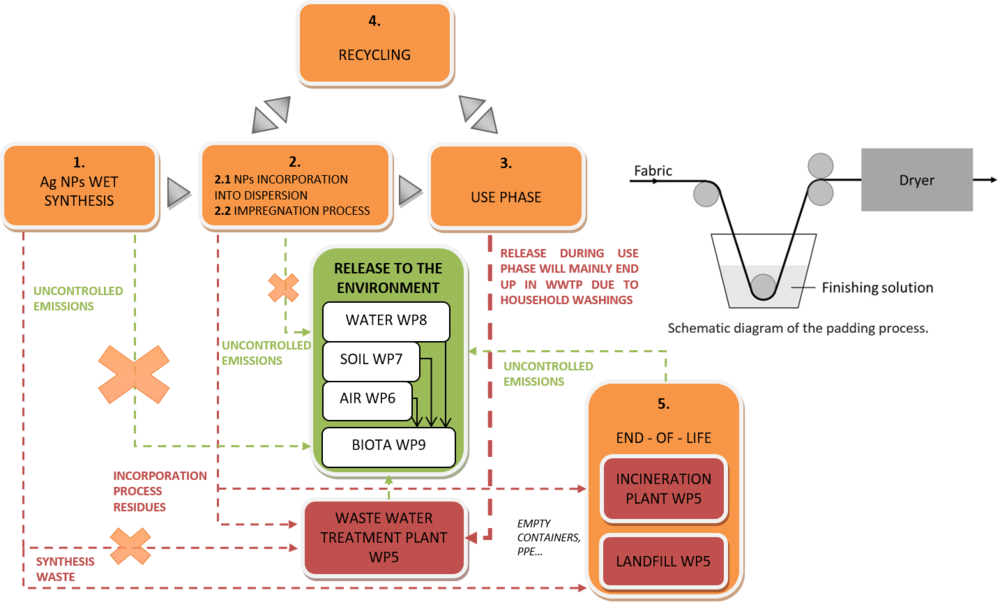

NanoFASE partner INOTEX is a small private research, innovation and technology transfer company in the Czech Republic in wet processing of textiles and (multi)functional textile developments using new methods and proprietary pilot production. The case study assessed in NanoFASE is INOTEX’s cotton fabric modified with a dispersion of silver (Ag) nanoparticles stabilized with polyvinylpyrrolidone (PVP), providing antibacterial properties to the textile. The NanoFASE experimental study was a small-scale test demonstration exploring production methods of smart textiles. The pathway analysis showed factory processes would result in no measured release of nanoparticles to the environment.

-

Synthesis: The liquid waste from synthesis contains a tiny amount (≤ 0.1 wt%) of Ag nanoparticles, delivered as hazardous waste to controlled treatment.

-

Impregnation process: Ag NPs are dispersed in the impregnation bath, which is incorporated in the textile by a padding process.

Phases 1 and 2 taking place in the factory demonstrated no release of nanomaterials to the environment. Phases 3, 4 and 5 are generic to nano-enabled fabrics such as those in many existing sports garments. The release of material from treatment of textiles such as washing is in line with expectations. -

Use phase: Release of Ag particles in the forms Ag+, AgCl and Ag 0is mainly due to household washings and can be very variable, ranging from 1 to 50% NPs release in a single wash cycle.

-

Recycling: Theoretically, when textiles are recycled after placement by users in specialized bins some ENM could be released and/or incorporated into second-generation textiles. In practice the amount of ENMs remaining in textiles is very likely close to zero due to the release during the use phase.

-

End-of-life: Textiles are usually disposed of as urban waste, incinerated or placed in landfill.

Read more |

|

D1.2 Report on the pathway analysis |

Contact

Socorro Vázquez-Campos

Socorro Vázquez-Campos

Email: svazquez@leitat.org

Olga Chybová

Olga Chybová