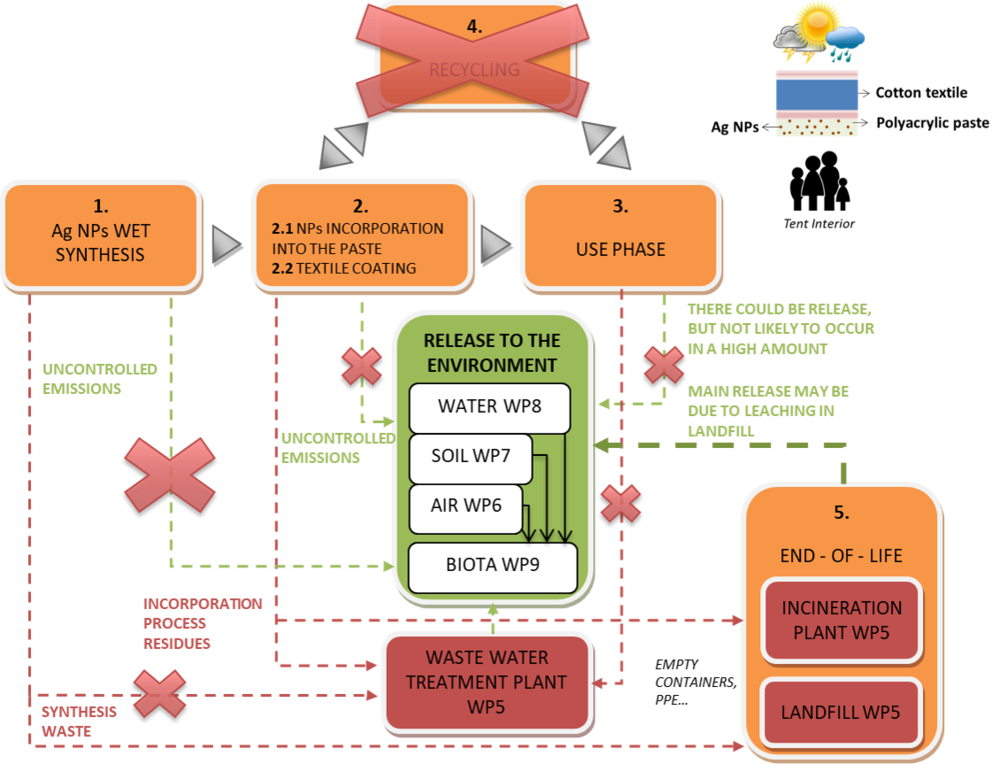

NanoFASE Case study: Camping tent canvas

NanoFASE partner INOTEX is a small private research, innovation and technology transfer company in the Czech Republic developing wet processing of textiles and (multi)functional textiles using new methods and proprietary pilot production. The case study assesses a cotton canvas fabric modified to become watertight with an impermeable layer of polyacrylic coating paste containing Ag nanoparticles. The resulting textile-based composite is intended to be used as a material to manufacture camping tents. According to INOTEX, the Ag presence diminishes the potential harmful effect of microorganisms on the fabric, avoiding undesirable effects such as the appearance of mould or bad odour. The pathway analysis showed that factory processes would result in no release of silver to the environment, with leaching as a possible vector of release at the end-of-life phase (landfill-managed waste).

- Synthesis: The liquid waste from synthesis contains a tiny amount (≤ 0.1 wt%) of Ag nanoparticles, delivered as hazardous waste to controlled treatment.

- Textile coating: The nanoparticles are mixed with a polyacrylic paste, which is then used to coat the textile. All the processes are done using wet chemistry.

- Use phase: in Release of Ag particles would result only in the event of degradation of the entire textile layer. This is considered unlikely to happen in the use phase.

- Recycling: Camping tents are usually disposed of as a whole; the textile contained in it is not typically sorted and recycled.

- End-of-life: When the tent is disposed of in landfill, Ag nanoparticles release could occur due to leaching.

Read more |

Contact

Socorro Vázquez-Campos

Socorro Vázquez-Campos

Email: svazquez@leitat.org

Olga Chybová

Olga Chybová