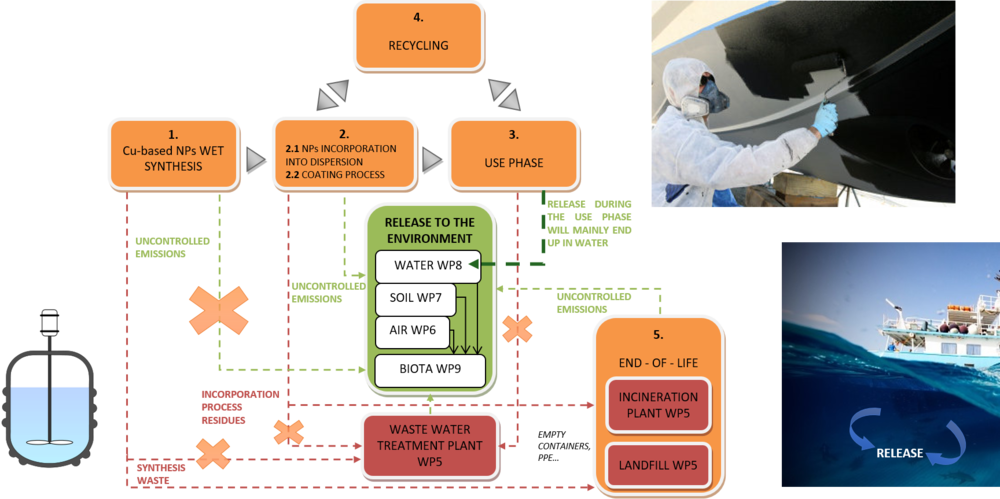

NanoFASE Case study: HEMPEL Antifouling Paint for Marine Activities

NanoFASE partner HEMPEL A/S is one of the leading coating companies for the marine and yacht market. HEMPEL has delivered antifouling solutions to customers all over the world for more than 100 years; several thousand vessels are painted every year with their products. HEMPEL's research lab has been exploring the benefits of using nanomaterials in coating products. The NanoFASE case study presented involves a comparison between nano and non-nano copper-based active compounds (Cu2O) regarding functional performance and potential release pathways. The copper-based nanomaterial was provided by NanoFASE partner Promethean Particles as a liquid thus eliminating occupational risk of inhalation during the paint mixing process.)

- Synthesis: The liquid waste from synthesis contains a tiny amount (≤ 0.1 wt%) of Cu-based nanoparticles, delivered as hazardous waste to controlled treatment.

- Coating process: HEMPEL antifouling paint is applied to vessel surface of approx. 300.000 m2/year. NanoFASE is currently assessing in lab-based experiments the release potential for such surface.

- Use phase: The antifouling paint can contain up to 45 wt% of Cu. Friction of water against the sides of the sailing vessel reduces the paint thickness by approximately 4 μm per month. Thus some quantityof Cu-based nanoparticles (under assessment) would be continuously released to the sea.

- Recycling: No recycling route exists.

- End-of-life: Old paint is commonly removed by sanding the surface before painting again. During this process ENM could be released to air due to mechanical stress.

Read more |

|

Visit the NanoFASE Library to read summaries of these reports: NanoFASE Report D1.2 Report on the pathway analysis |

Contact

Socorro Vázquez-Campos

Email: svazquez@leitat.org

Marta Santiago

HEMPEL

Selina Tang

Promethean Particles