Accidental release to air during synthesis and handling in industrial processes

While systematic efforts are made to prevent them, accidental releases may generally still occur in the chemical industry. Major releases are very rare events, but if they occur, they can contribute significantly to the emission of chemicals to the environment.

As the nanomaterials industry develops, the Responsible Innovation approach means that scenarios for accidental releases of nanomaterials are analysed in order to design systems of prevention and control. NanoFASE also takes such potential events into account in its exposure assessment approach.

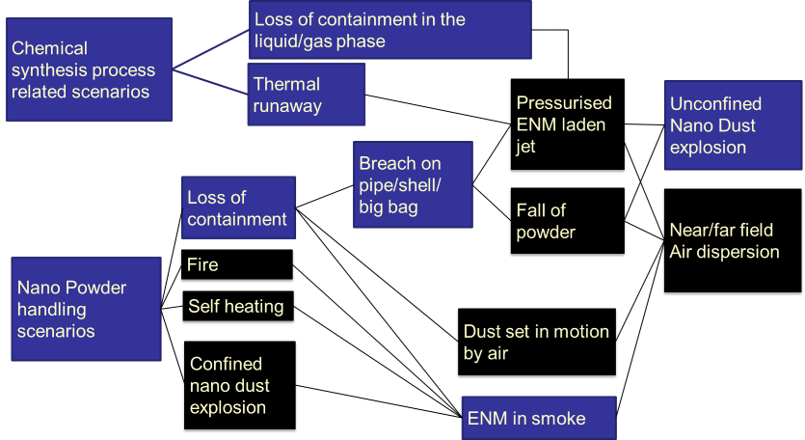

At each stage of the ENM life cycle, accident scenarios potentially can take place that lead to unintended or uncontrolled releases of ENM to different environmental compartments: air, water or soil. Below a sample scenario analysis is displayed for the case of the air compartment.

|

Released to |

|

|

|

Release rates and amounts |

|

|

Release rates and amounts are very dependent on the release scenario, the safety procedure in place and the location and environment of the release. They can range from a few kg for small releases to several tons in rare cases of major releases. Several uncontrolled releases involving ENMs have occurred in the past among which are the two following illustrative events. These accidents had no reported health or environmental consequences but resulted in the release of measurable amounts of ENMs to the immediate surroundings.

Source : https://www.aria.developpement-durable.gouv.fr/accident/43049/

|

ENMs most commonly handled in industry: SiO2, Carbon Black, CaCO3,TiO2 Main release scenarios: Leak from pressurized pipe Leak from pressurized tank Leak of air treatment filter Breach on tanker during transport (road, rail) Breach of bulk bag due to fall (on-site or during transport) Fall from height due to mechanical damage to transport equipment (hopper, band conveyor) Breach of small container or bag during handling ENM forms observed at release: ENM aggregates |

Release forms |

Case study: Modelling release from a pressurised pneumatic transport pipe |

|

Under an accident scenario the release form is directly related to the form of ENMs used in the industrial process. NPs typically agglomerate with agglomerate sizes in the micrometric range. Modelling and experiments have shown that once formed, these agglomerates remain mostly unchanged during their dispersion in air, at least in the near field.

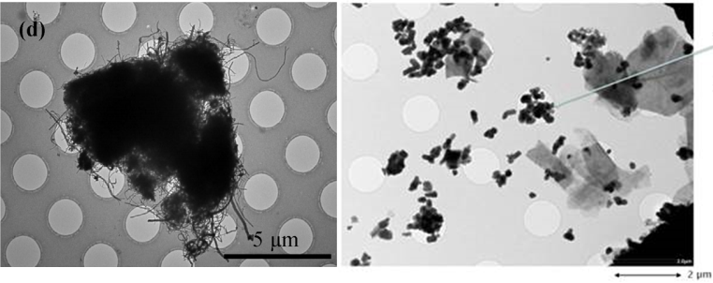

Examples of Carbon Nanotube (left)1 and TiO2 and Kaolin Agglomerates (right)2 collected in or around industrial processes due to ‘normal’ controlled emission (not accidental emission) Source : 1C. Bressot et al. / Process Safety and Environmental Protection 116 (2018) 324–332

|

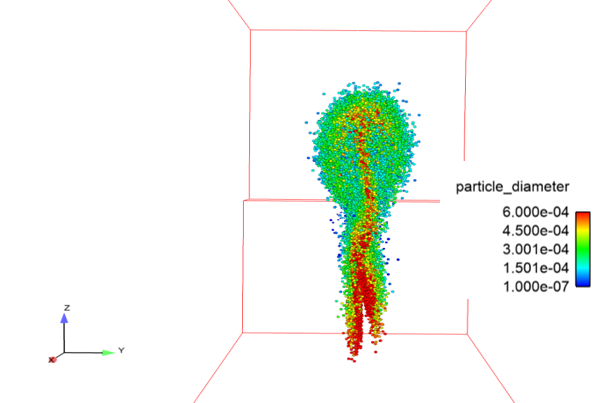

A model was developed in the framework of a CFD (computational fluid dynamics) approach using Code_Saturne to estimate the release form in case of ENMs leakage from a pressurized pneumatic transport pipe. The model takes into account the main phenomena that govern particle motion and agglomeration in the first meters of distance from the site of breach: drag on agglomerates, agglomerates breakage by fluid and agglomeration of agglomerates. It is intended to provide relevant data for air dispersion models at longer range, in particular the size distribution of agglomerates.

Read more: Hong Duc LE, Modelling of nanoparticles-laden jet from a conveying pipe leakage. PhD thesis defended on 4th of June 2018 at INERIS (in collaboration with Institut de Mécanique des Fluides de Toulouse). |

Modelling the air dispersion in accidental release scenarios

|

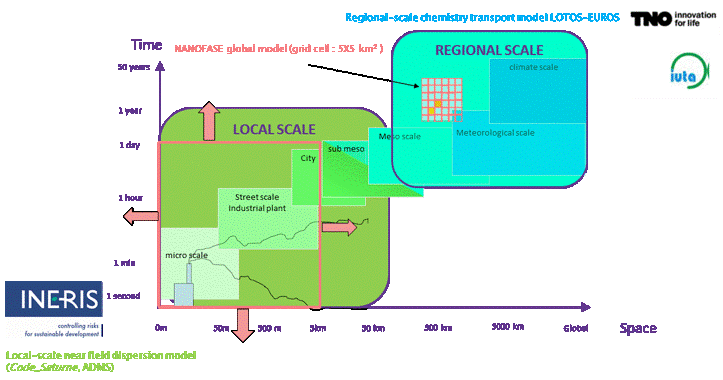

Risk assessment requires that the consequences of an accidental event be estimated in terms of level of exposure of diverse sensitive targets. For the NanoFASE project, knowing what is transferred from the initial release to other compartments is essential. Atmospheric dispersion models are developed at various scales of resolution in time and space, from local very short-range (where emission and agglomeration phenomena occur) to long-range regional scale.

|

Read more |

Read also |

|

Visit the NanoFASE Library to read summaries of these reports: NanoFASE Report D4.4. Catalogue of potential accidental releases and accidental release model NanoFASE Report D6.4. Model development and evaluation of model quality for airborne ENM |

John AC, Kupper M, Manders-Groot AMM, Debray B, Lacome J-M, Kuhlbusch TAJ. Emissions and possible environmental implication of engineered nanomaterials (ENMs) in the atmosphere. Atmosphere, 2017, 8 (5) : p. art. 84 Le HD, Sommerfeld M, Fede P, Climent E, Truchot B, Debray B, Lacome J-M, Vignes A. Collision probability coefficient between an agglomerate and a spherical particle and between two agglomerates by Monte-Carlo method. Submitted to Journal Powder Technology, 2018 |

Contact

Bruno Debray

Bruno Debray

Email: bruno.debray@ineris.fr

Jean-Marc Lacome

Email: jean-marc.lacome@ineris.fr